Opulo Order Fulfillment SOP

Deciding What to Fulfill

-

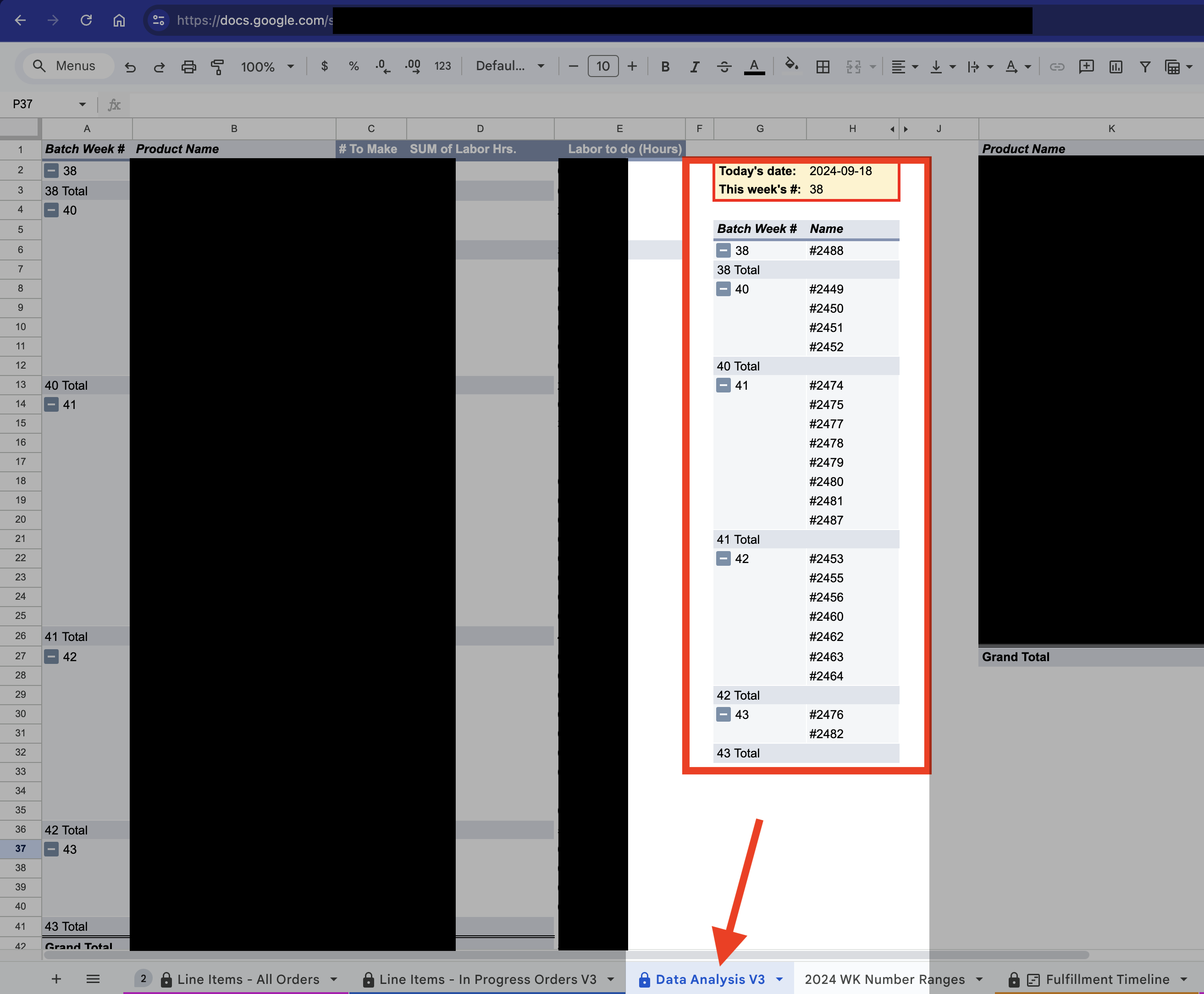

Review Coeffient V3 to see which orders should be shipped based off their

Batch WK#- Orders are sorted into a given

Batch WK#based off theirPlanned Ship Date, which may differ from theOrder Due Date

See here for more information on our Planned Ship Date calculations

- Orders are sorted into a given

-

Go to ShipStation and create a batch for the orders that fall within the given

Batch WK#you wish to fulfill.- Name the ShipStation batch to

Batch WK#, where#is replaced with the batch's given week number - Be sure to select the correct box size for the items and ask for help if needed

- Name the ShipStation batch to

Prepare the Order-Packing-Checklist

-

Prepare an

Order-Packing-Checklistfor the week's fulfillment using the Google Slides template- Make a copy of the most recent slide and replace the image with the screenshot of the ShipStation batch you are working with

-

The checklist printout should look like the following image:

-

Fill in the time and date for any scheduled pickup, per carrier

- Write "Drop off" for any carrier that we will bring the packages to ourselves

-

Print out the week's checklist when ready

Purchasing Shipping Labels

-

Review each ShipStation order in the batch for correctness - double check the package size, declared values, and shipping methods are all appropriate

Training is required for this step

Please ask Lucian for help if it's your first time doing this.

-

Purchase the labels

Create a Pickup

-

Set the

Pickup Datefor the required shipping carriers -

Customers can currently pick between UPS, USPS, and DHL at checkout so multiple pickups may be required

-

Print out all the shipping labels for the week on

4x6 Label Paperwith the Dymo 4XL Label Printer

Handling the Shipping Paperwork

-

Separate the shipping labels by order number, leaving related shipping label(s) and packing slips connected

-

Domestic shipping labels will have 2 pages per order, these are:

- Shipping Label

- Packaging Slip

-

International shipping labels will have 2 or more pages per order, these are:

- Shipping Label

- Packaging Slip

-

Customs Declaration (3x copies, printed seperately on A4 paper)

DHL does not require a Customs Declaration Sheet

This information is electronically transmitted to Customs agencies automatically

-

-

For International Orders Only:

- Sign all copies of the

Customs Declaration Form - Place all signed copies of the

Customs Declaration Forminto a resealable adhesive-backed plastic document holder - Paper clip the

Shipping LabelandPacking Slipto the front of the plastic document holder

- Sign all copies of the

Packaging Orders

- Begin packaging orders by working through the

Order Packing Checklist - Reference the

Order-Packing-Checklistto determine what packaging is required for the week's fulfillment - Check-off and write in your initials on the printed

Order-Packing-Checklisteach time an order is packaged and taped shut

Additional Guidelines for Packaging

- Shipments with a pending payment status

- Alert customer service when these orders are ready for shipping , so that the team is given notice when an order with NET## terms has been shipped out

- Shipment comprised of two or more packages poly-strapped together:

- Adhere the shipping label and other documents to the largest package in the shipment

- Take care to avoid the shipping documents being obstructed by the poly-straps

- Write the

order numberonto the smaller boxes within the bundle using a large marker- This is done to help the shipping carrier if the bundle breaks apart in transit

The Order-Packing-Checklist lists what package type an order requires if you are unsure or found the shipping documents sorted into a vague pile

Serialization and OQC Form Requirements

Shipments that contain a uniquely serialized product (LumenPnP, PCB Kit, Replacement Motherboards) must be logged in the LumenPnP - Serial Tracker and OQC Form

- Shipments that contain a LumenPnP must have an orange fragile sticker adhered to the box after being taken through this form

Outgoing Quality Control (OQC)

-

Sort the taped boxes into the following stacks:

- DHL

- USPS Domestic

- USPS International

- UPS Domestic

- UPS International

-

Confirm the following:

- Docker does not have any assembled goods beyond what's expected to be in

unfulfilled inventory - There is exactly as many packages ready to ship as what's shown in the

order-packing-checklist - Each line in the

order-packing-checklistis checked-off and initialed - No unused shipping labels are left sitting out

- The first page of any international shipment's custom form matches the receiver's name on the shipping label

- Docker does not have any assembled goods beyond what's expected to be in