Drive Wheel Assembly

This section will guide the reader on how to prepare and glue the shaft-collar-asm onto drive-wheel to create drive-wheel-asm.

Prepare shaft-collar-asm

-

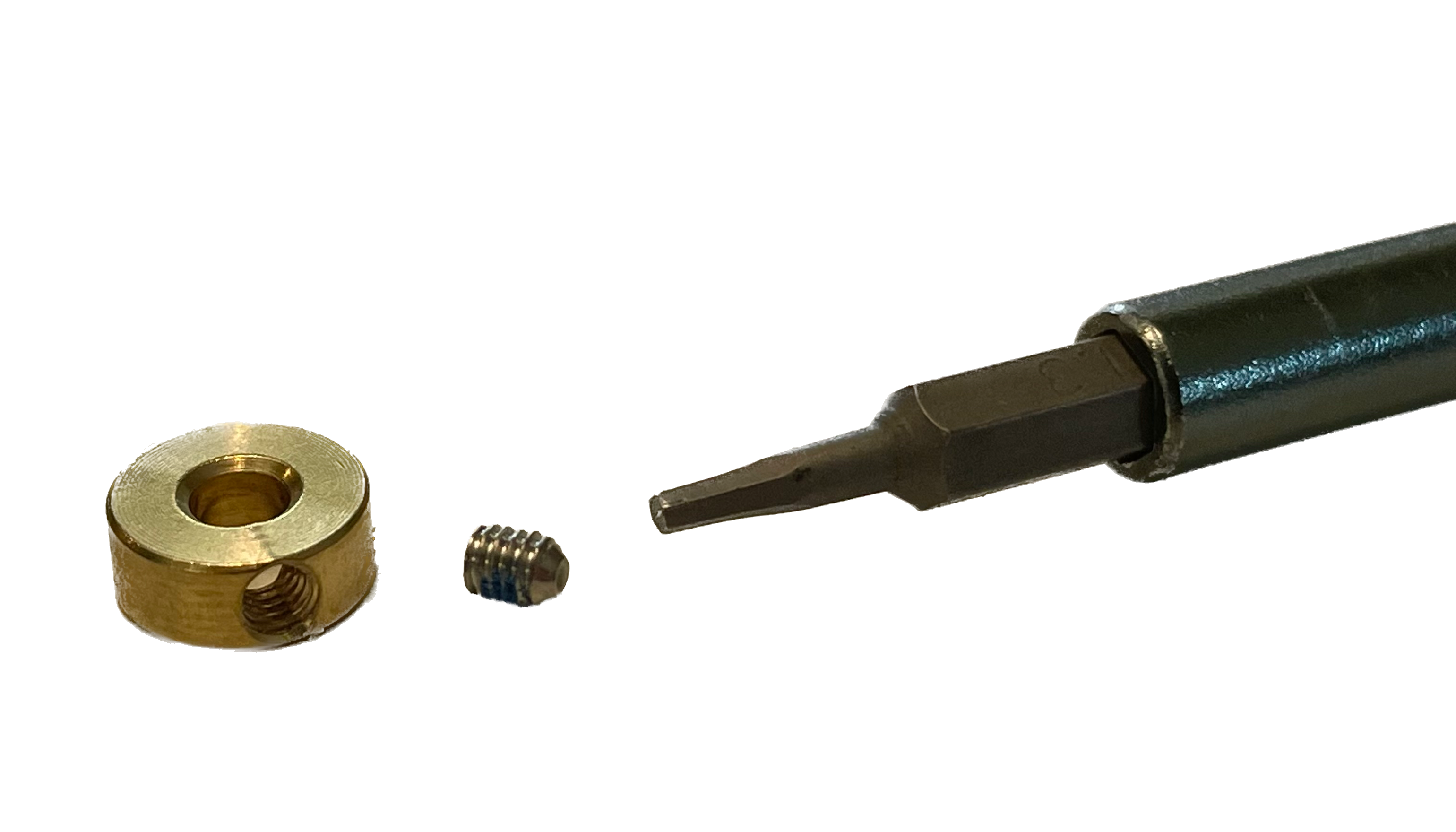

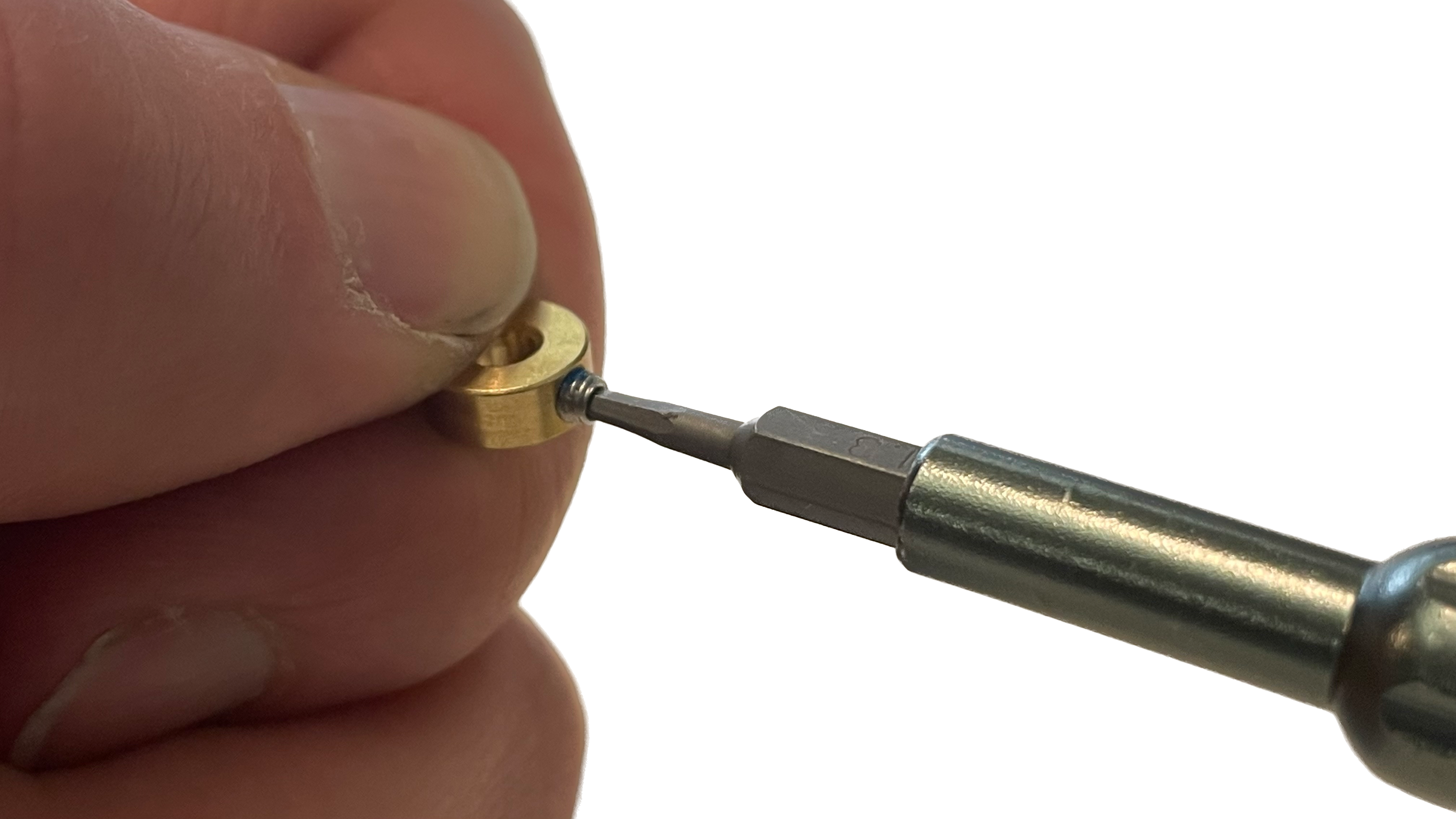

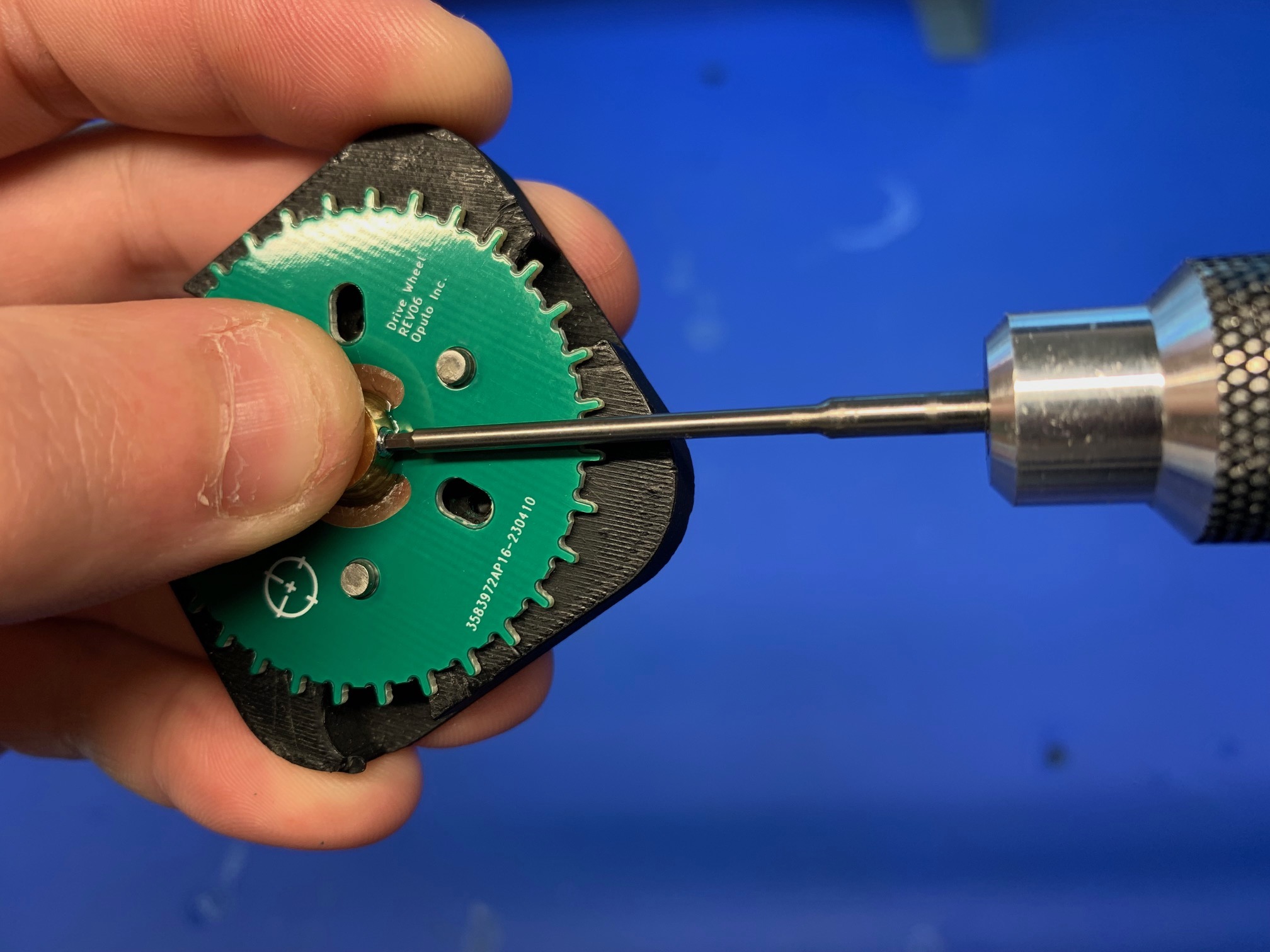

Install the

set-screwinto theshaft-collarwith a1.3mm hex driver

-

Tighten the

set-screwuntil it nearly passes into the inner bore

Install shaft-collar-asm and drive-wheel onto shaft-alignment-jig

-

Place

drive-wheelonto theshaft-alignment-jig- Let the 3 slotted pins help align the

drive-wheelinto position - Push the

drive-wheeldown firmly to ensure it is fully seated onshaft-alignment-jig

- Let the 3 slotted pins help align the

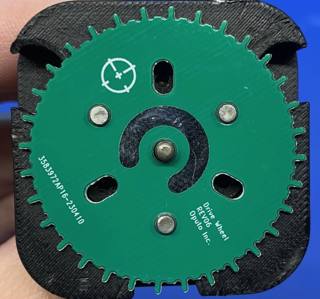

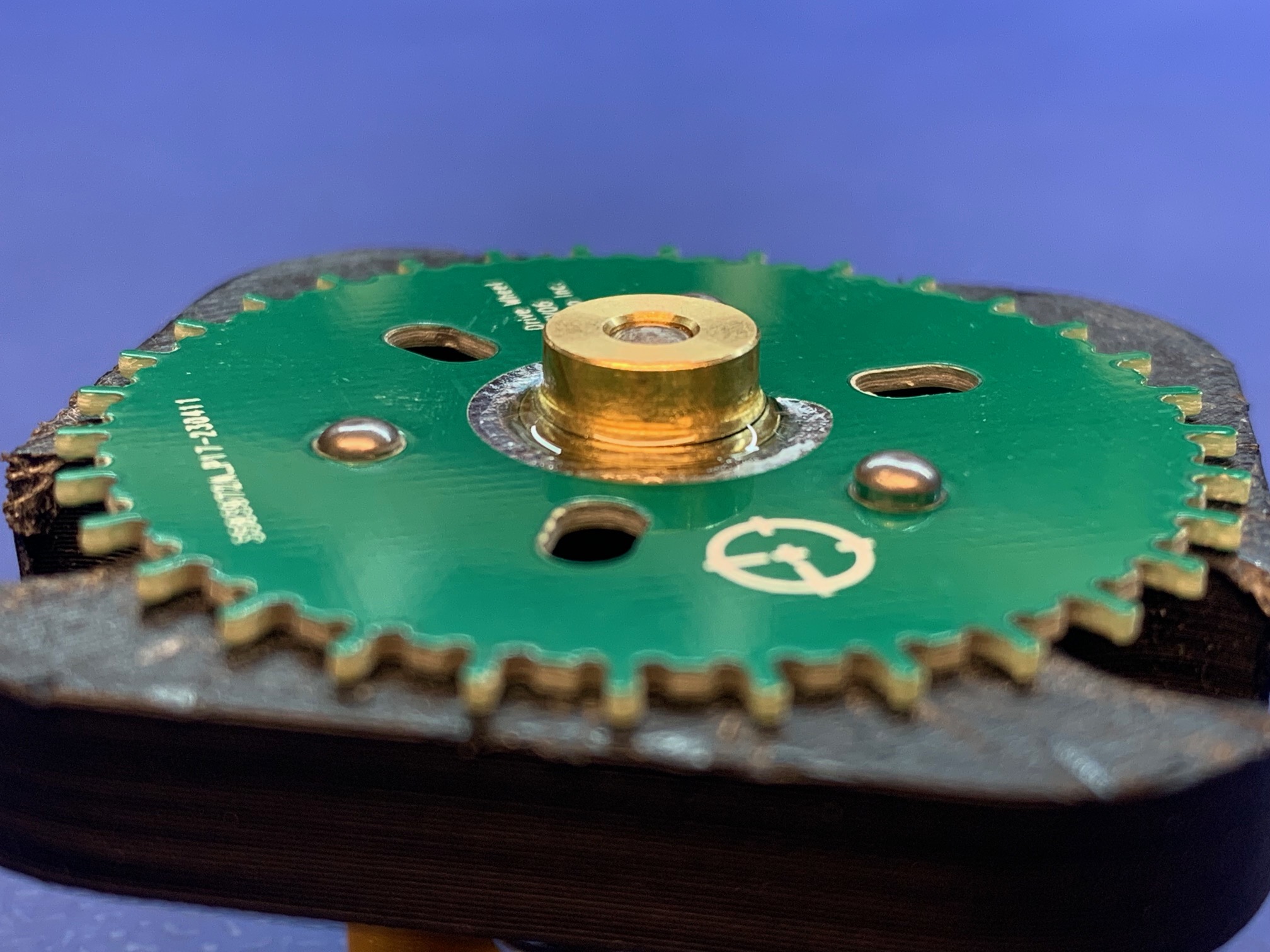

Make sure that no part of drive-wheel is touching the center post of shaft-alignment-jig

* Otherwise, something may become misaligned or unintentionally glued together

* The image below shows a `drive-wheel` with OK clearance from the center post of `shaft-alignment-jig`

-

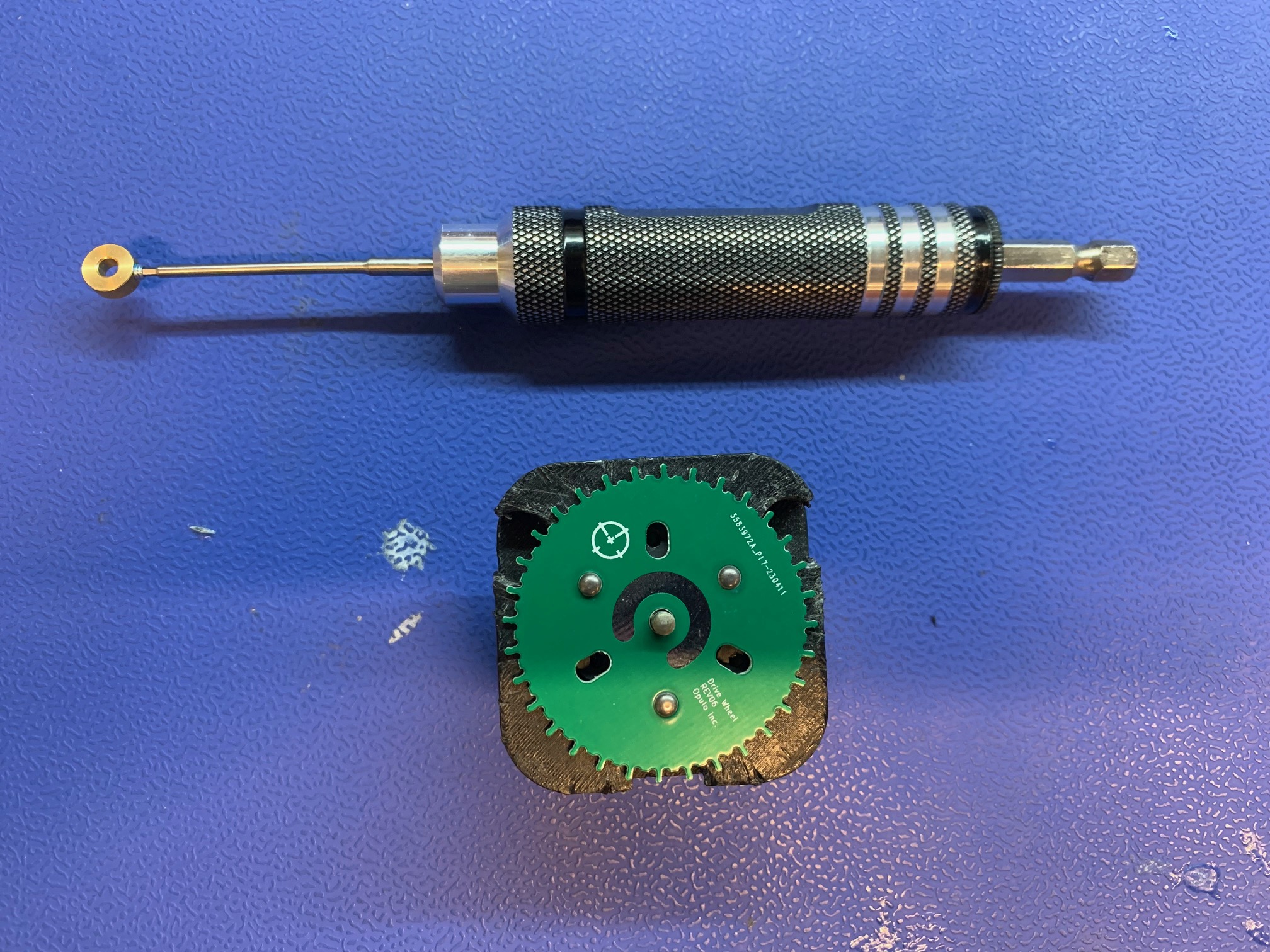

Place

shaft-collaronto the center post ofshaft-alignment-jig- Orient

shaft-collarso theset-screwis above the green soldermask ondrive-wheel

- Orient

-

While firmly pressing

shaft-collar-asmdownward, tighten the set-screw to0.2 N/MWarning

Make sure that the shaft-collar-asm does not lift up as you tighten the set-screw

Inspect the WIP assembly for visible daylight between drive-wheel and shaft-collar-asm

If there is a noticeable gap between these two items, adjust and retighten shaft-collar-asm as needed.

-

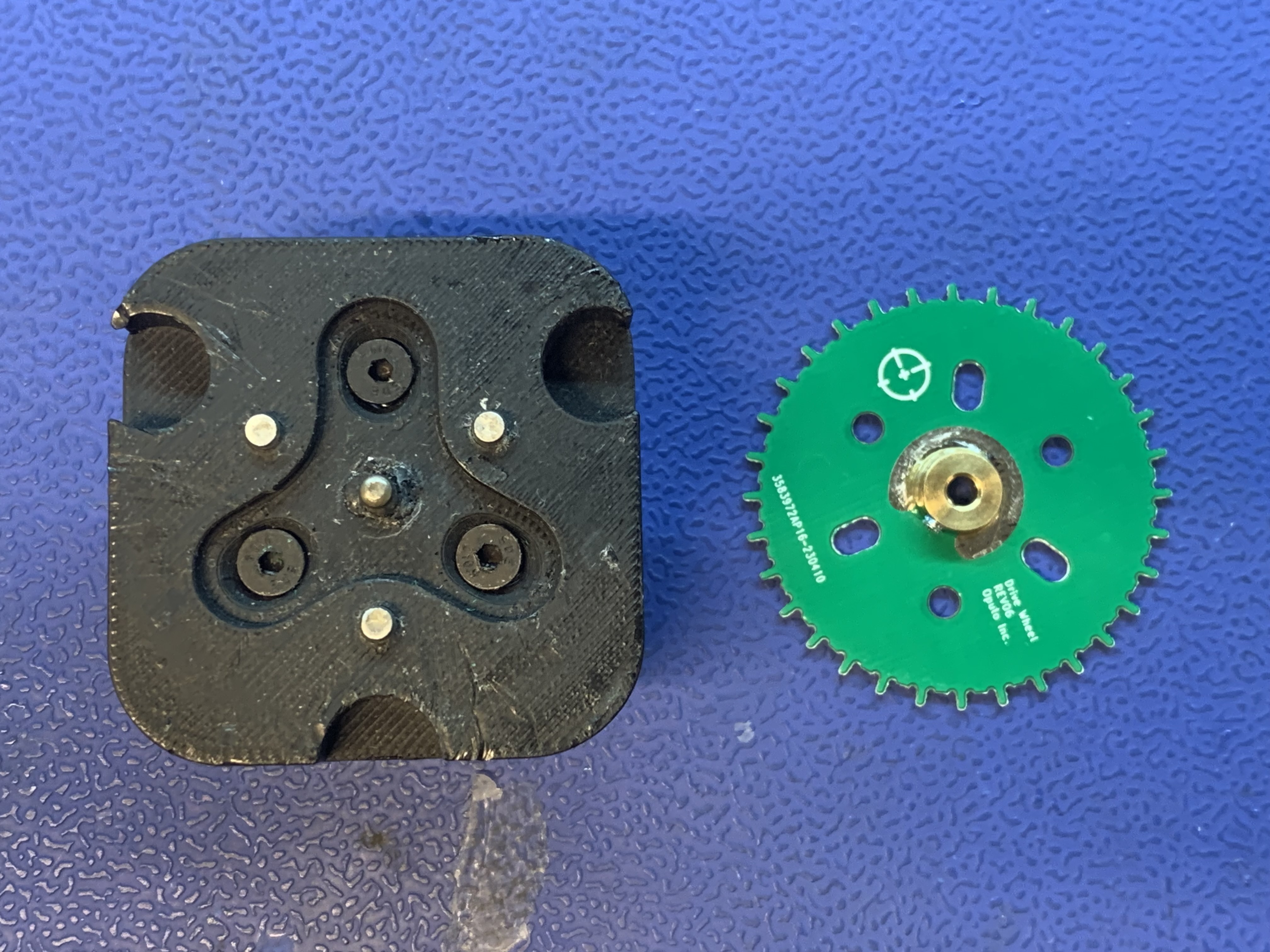

When the above steps are completed, the WIP assembly should match the image below -

Glue shaft-collar-asm and drive-wheel together

-

Apply

LOCTITE 435to the seam betweenshaft-collar-asmanddrive-wheel- Rotate around the

shaft-collar-asmwhile slowly dispensing glue - Only apply glue to the C-shaped region of

drive-wheel, being sure to avoid getting glue anywhere near theset-screw

Note

If you accidentally dispense too much glue initially, stop and follow the note below

- Gently swirl the

shaft-aligment-jigwith affixed WIPdrive-wheel-asmaround to spread the glue around the silver C-shaped pad - As usual, be sure to avoid getting glue anywhere near the

set-screw

- Rotate around the

-

Allow the

LOCTITE 435to dry for 180 seconds before proceeding -

Remove the completed

drive-wheel-asmfrom theshaft-alignment-jig- Loosen the

set-screwwhile pinching down on theshaft-collar- This will help to avoid unneeded stress to partially cured glue

- Remove the

drive-wheel-asmby pressing the outer-edges ofshaft-collar-alignment-jigdownward to actuate the jig's ejector pins

- Loosen the

-

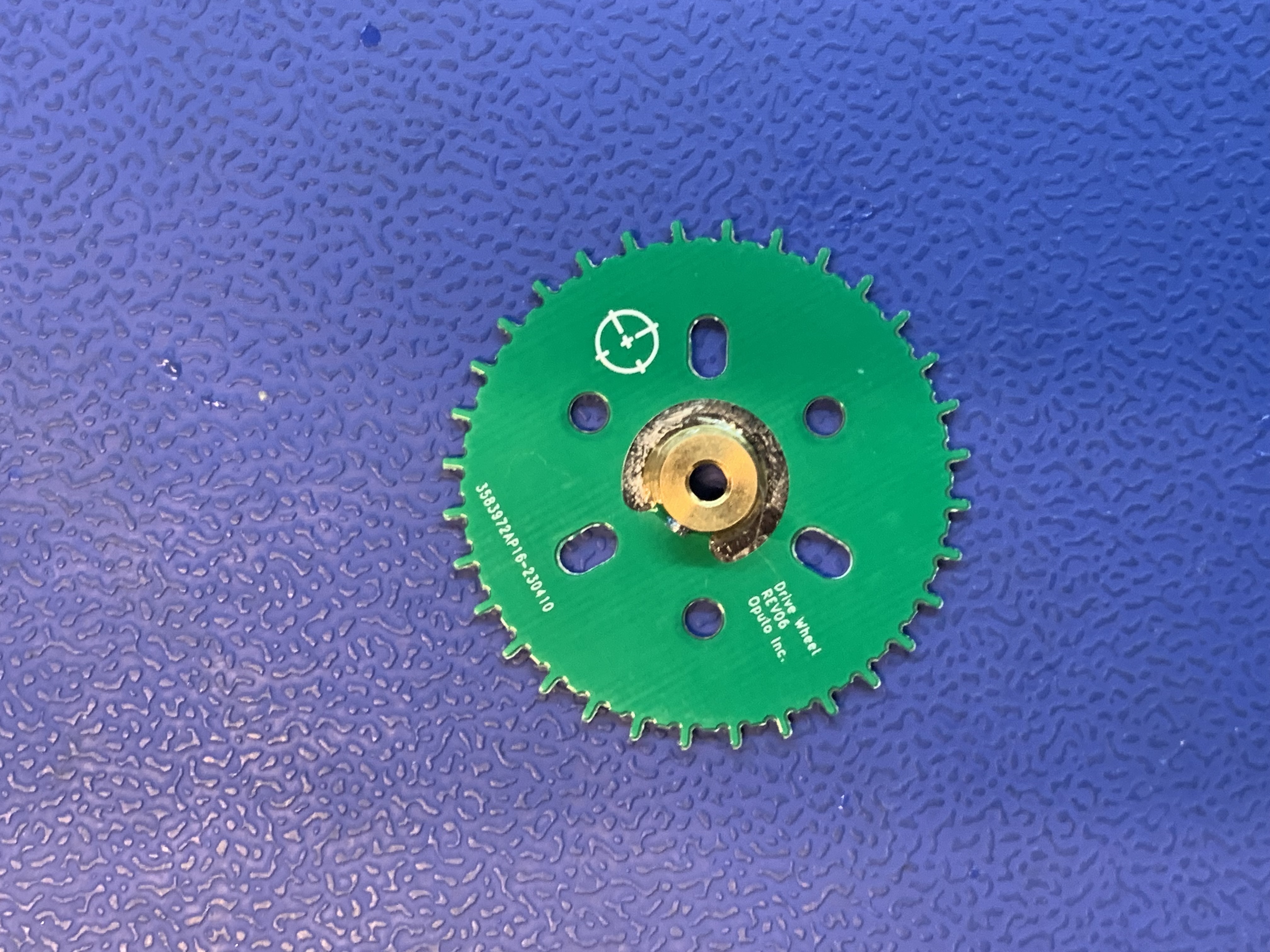

Allow the completed

drive-wheel-asmto dry for 1 hour before using it in further processes- The

drive-wheel-asmshould sit flat on a table while it finishes drying

- The

-

Once an hour has passed, check that the

shaft-collaris glued on firmly by nudging it laterally- Note that the outer surface of the glue bond may remain tacky for several more hours

If the shaft-collar moved when testing the glue bond strength, scrap the drive-wheel-asm and record the wasted material

If the glue strength is OK, move the completed drive-wheel-asm to its corresponding storage bin at the feeder assembly workstation