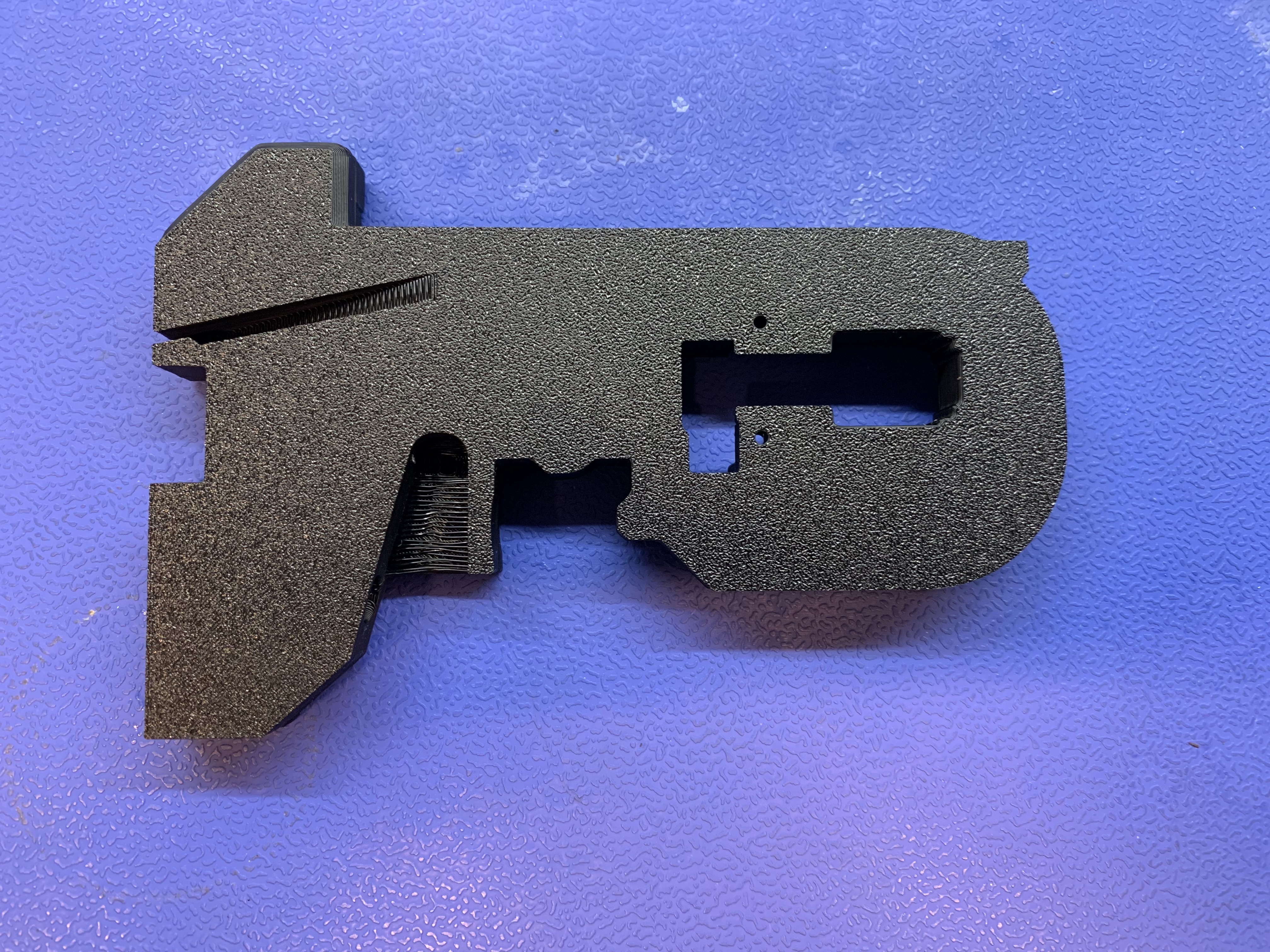

8mm Feeder Frame Assembly

This section will guide the reader through the process of installing various hardware components into feeder-frame-8mm in preparation for its use in final assembly.

Prepare feeder-frame-8mm

-

Inspect the print for defects

- Use a heat gun to remove any stringing

- Check the first layer to ensure it is free of defects and printed on the tuxtured print bed as shown

- Firmly press the up and down buttons so that they can move freely

Note on button handling

- These buttons are print-in-place flexures, which means they need to be broken away from the layer of plastic between them and the rest of

feeder-frame-8mm- Exercise care here, as pressing these buttons too far inward can break them

- The motherboard that is installed later will prevent this type of button over-travel damage

-

Inspect for loose plastic in the overhanging region of the pick-window on the

feeder-frame-8mm- Remove any loose plastic with a knife as needed

Rework Needed

OK

Install Light Diffuser

-

Use an

arbor-press-jigto installlight-diffuser-pcb (PCB-0013-01)intofeeder-frame-8mm- The Opulo logo on

light-diffuser-pcbshould be in the correct orientation when the feeder is held in front of you

- The Opulo logo on

-

The installed

light-diffuser-pcbshould be flush to the top-face offeeder-frame-8mmwhen installed correctly

Install 8mm Fiducial Board

-

Add a small amount of

LOCTITE 435in the front pocket of thefeeder-frame-8mm

-

Manually install

8mm-fiducial-boardinto the front pocket offeeder-frame-8mm- The fiducial markers should remain visible when installed

-

Orient

feeder-frame-8mmupright for 30 minutes to allowLOCTITE 435time to cure