Feeder Connection Kit

This section will guide the reader on how to properly prepare the accessories that go into a feeder-connection-kit.

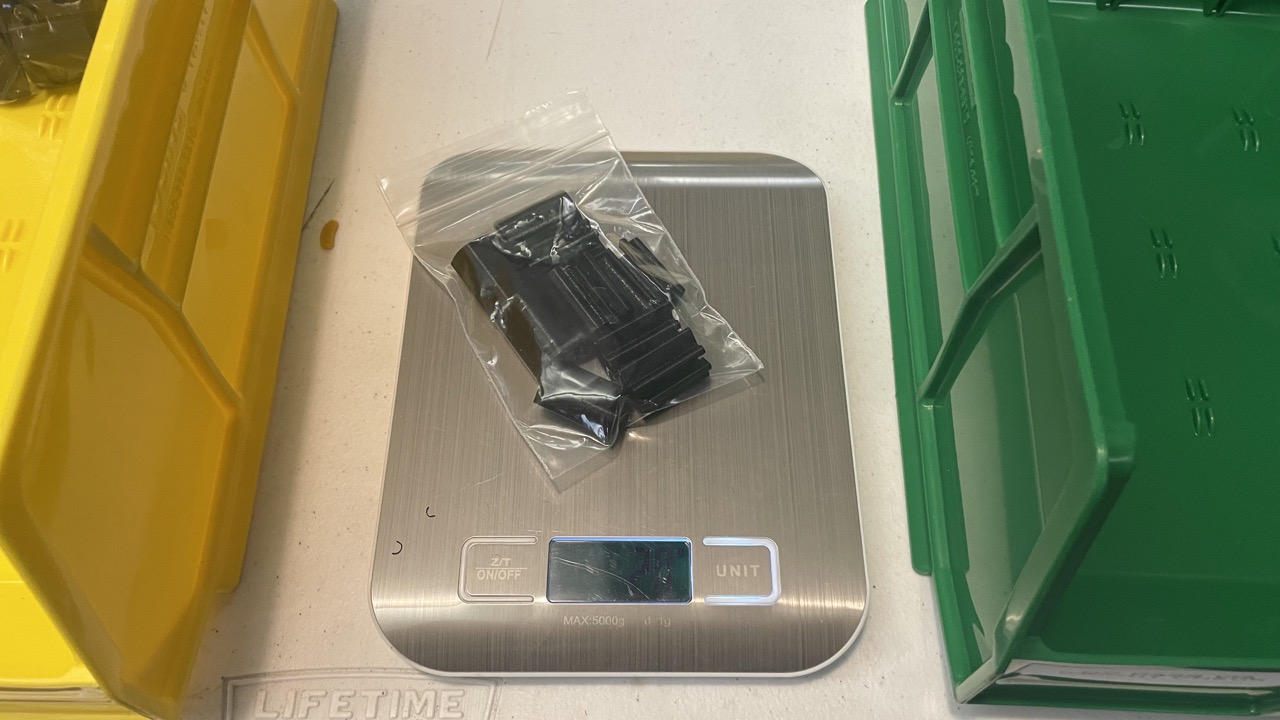

bagged-extrusion-cable-clips

-

Place 10x

extrusion-cable-clippieces into a3x4-bagbefore sealing it shut

-

Place each

bagged-extrusion-cable-clipsset into a yellow NEEDS QC bin while it awaits inspection

-

Weigh each

bagged-extrusion-cable-clips, confirming it weighs19.9g

-

Place the

bagged-extrusion-cable-clipspieces that pass weight check into a green QC-Pass bin

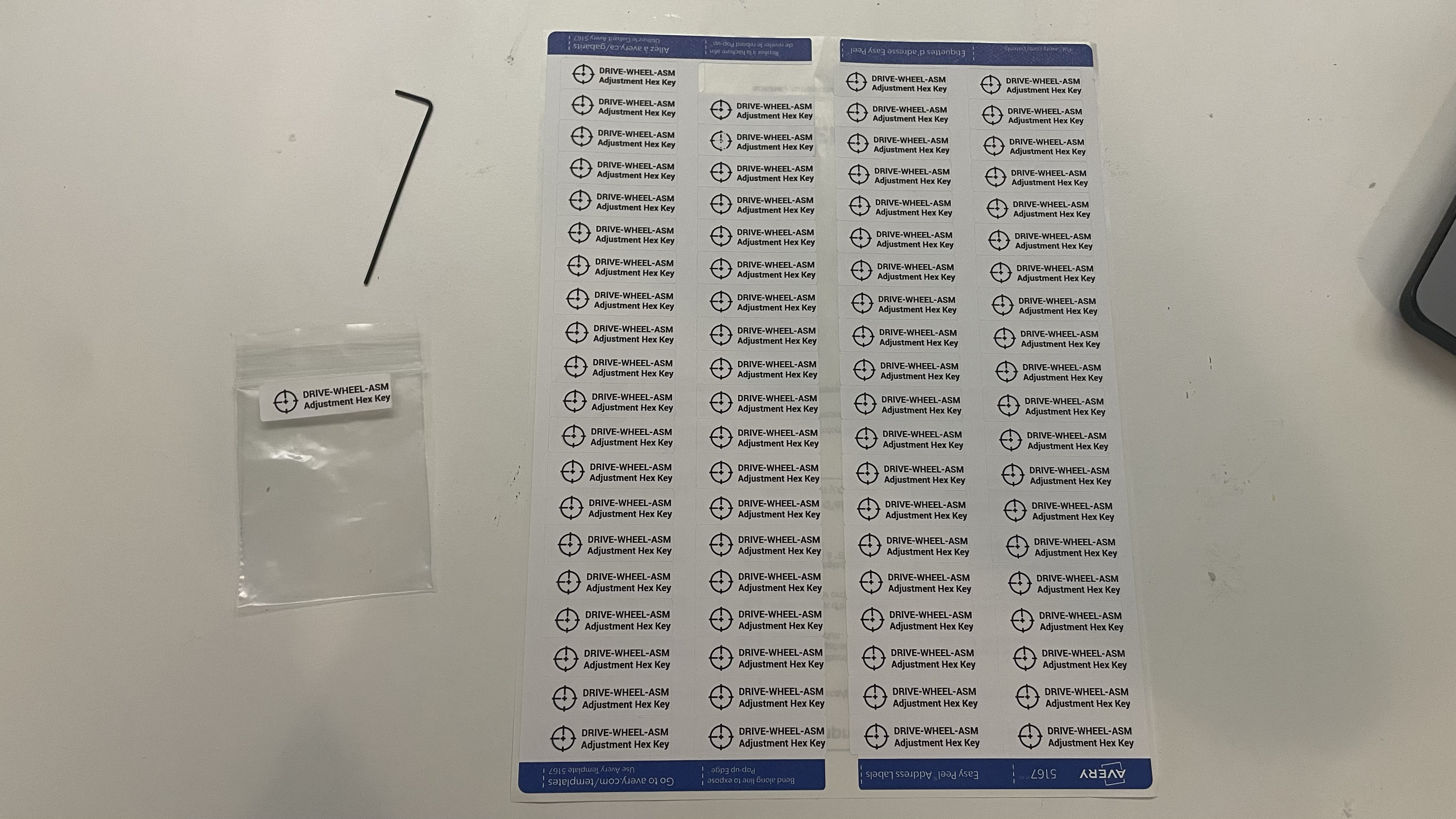

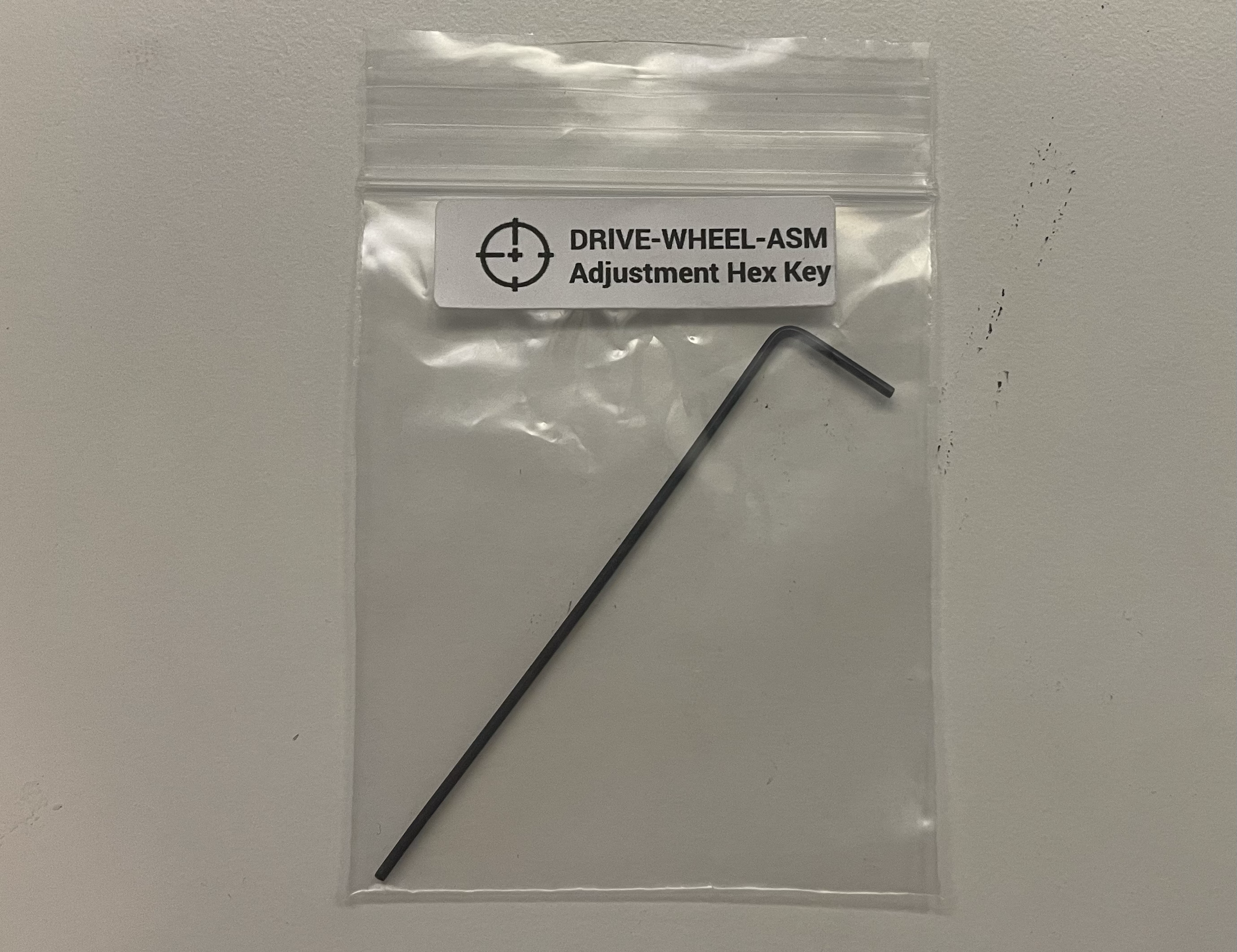

Hex Key for Drive Wheel Adjustment

-

Adhere a "hex key bag label" onto a

2x3-bag

-

Place a hex key into the plastic bag before resealing it

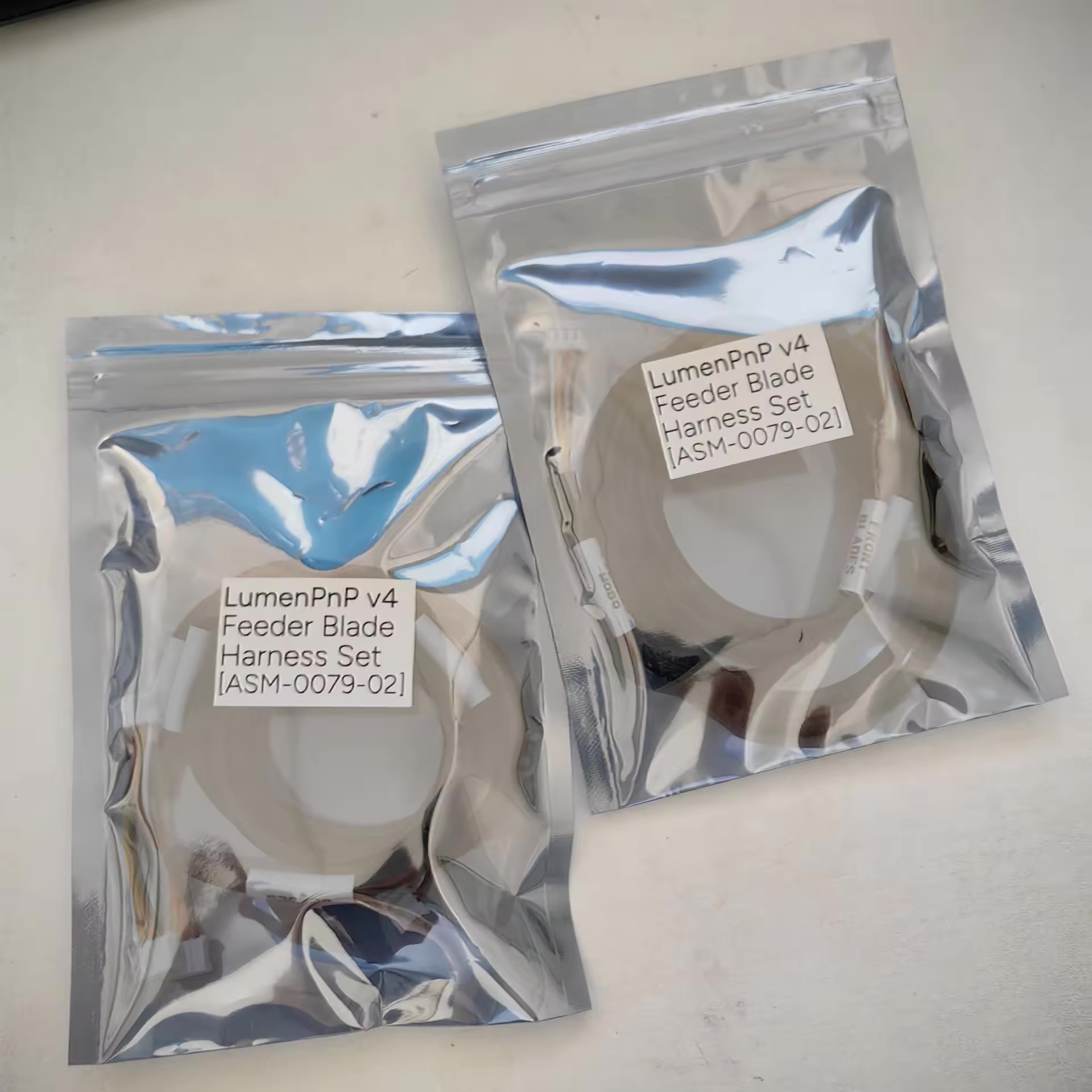

Collect feeder-blade-harness-set

-

Collect a

feeder-blade-harness-set[ASM-0079-02] from inventory

Feeder-cable-adapter

Assemble feeder-cable-adapter

- Create a

50mm-idc-ribbon-cablethat matches the image below - Assemble

feeder-blade-idc-adapter-pcba -

Glue

blade-adapter-pin-coveronto the PCBA -

Connect

50mm-idc-ribbon-cabletofeeder-blade-idc-adapter-pcba

Packing feeder-cable-adapter

- Add 1x

feeder-blade-idc-adapterand 2xblade-jumper-v4into2x3-bag - Seal bag shut

If the feeder-cable-adapter is being prepared for individual sale, adhere a build-number-sticker to the outside of the packaging

These assemblies can now be set aside for further use in packout