Staging Plate

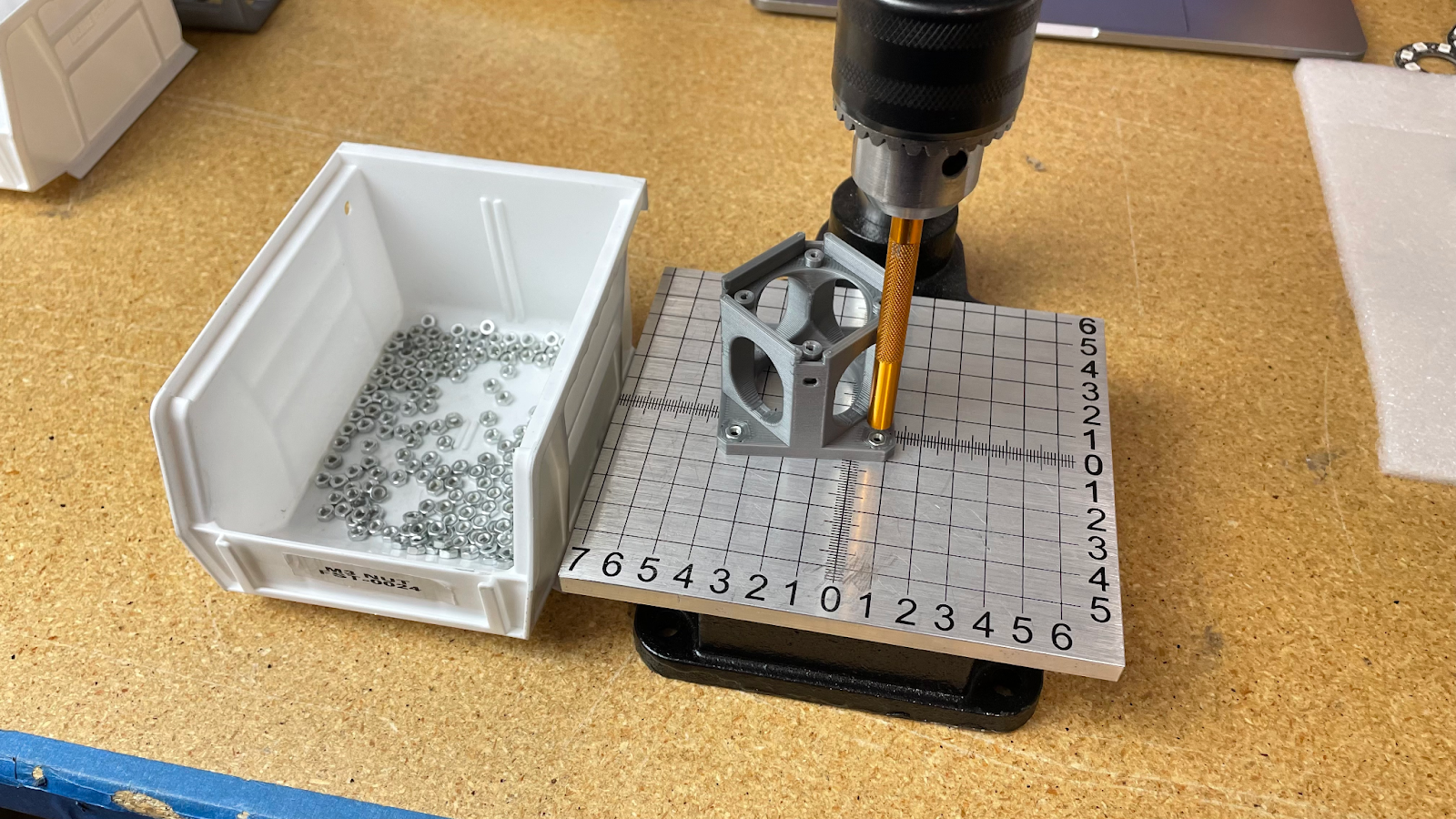

Install hardware into 3D printed components

- Use an arbor press to insert the given quantities of

M3-hex-nutinto the following parts: - 4x for

bottom-camera-mount -

3x for 3x

peek-cable-clampNote

Be sure to change the arbor press tip for the different prints as needed.

Removing punch-out from PCB-0003

-

Remove the punch-out from center of

PCB-0003with flush cutters

-

Clean up hole with a razor blade after punch-out has been removed

-

Clean both sides of

PCB-0003with an IPA-soaked shop rag

Focus the bottom-camera

-

Use

bottom-camera-focus-jigto pre-focusbottom-camera -

Loosen the set screw on the side of the lens, this will let the lens focal-point be adjusted

-

Be careful not to loosen it too much or the screw may fall out and get lost!

-

Remove the lens cap from

bottom-camera - Rotate the camera lens back and forth to loosen any glue

- Hold the PCB in one hand while twisting the lens body with your other hand

-

Don't be afraid to use a few pounds of force if needed

-

Install the

bottom-camerafully into thebottom-camera-focus-jig - Put the JST-side of

bottom-camerainto the jig first -

Connect the JST-side of the USB cable into the bottom-camera PCB

-

Connect the USB cable on

bottom-camera-focus-jigto a computer and open its native camera viewing application - Use Photobooth if on Mac OSX or Cheese if on Linux

- Confirm that the camera feed is running in 720p, sometimes it can launch in 360p or 480p

- Within the camera viewing application, change the selected camera to

PnP Bottomto view the camera feed of the bottom-camera

If the listed camera is something other than PnP Bottom, the device may either be incorrectly programmed or mixed up with a top-camera

Please take this as an opportunity to double-check the device name even if the computer switched to the correct camera feed automatically.

- Rotate the camera lens until the live viewport shows the datum board as focused as possible

-

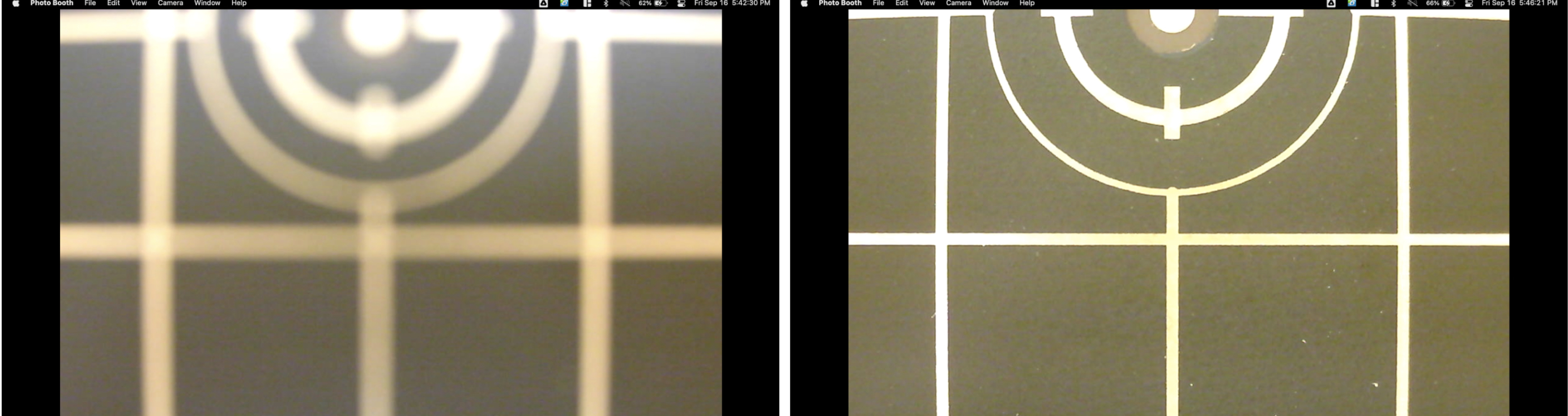

Before and after lens focusing:

-

Once the camera is focused, tighten the set screw to lock in the focus adjustment

-

Put a blue dot on the camera PCB with a sharpie to denote that the camera has passed testing

-

Remove the

bottom-camerafrom thebottom-camera-focus-jigand immediately replace the lens cap -

Return the

bottom-camerato the red esd-safe bag

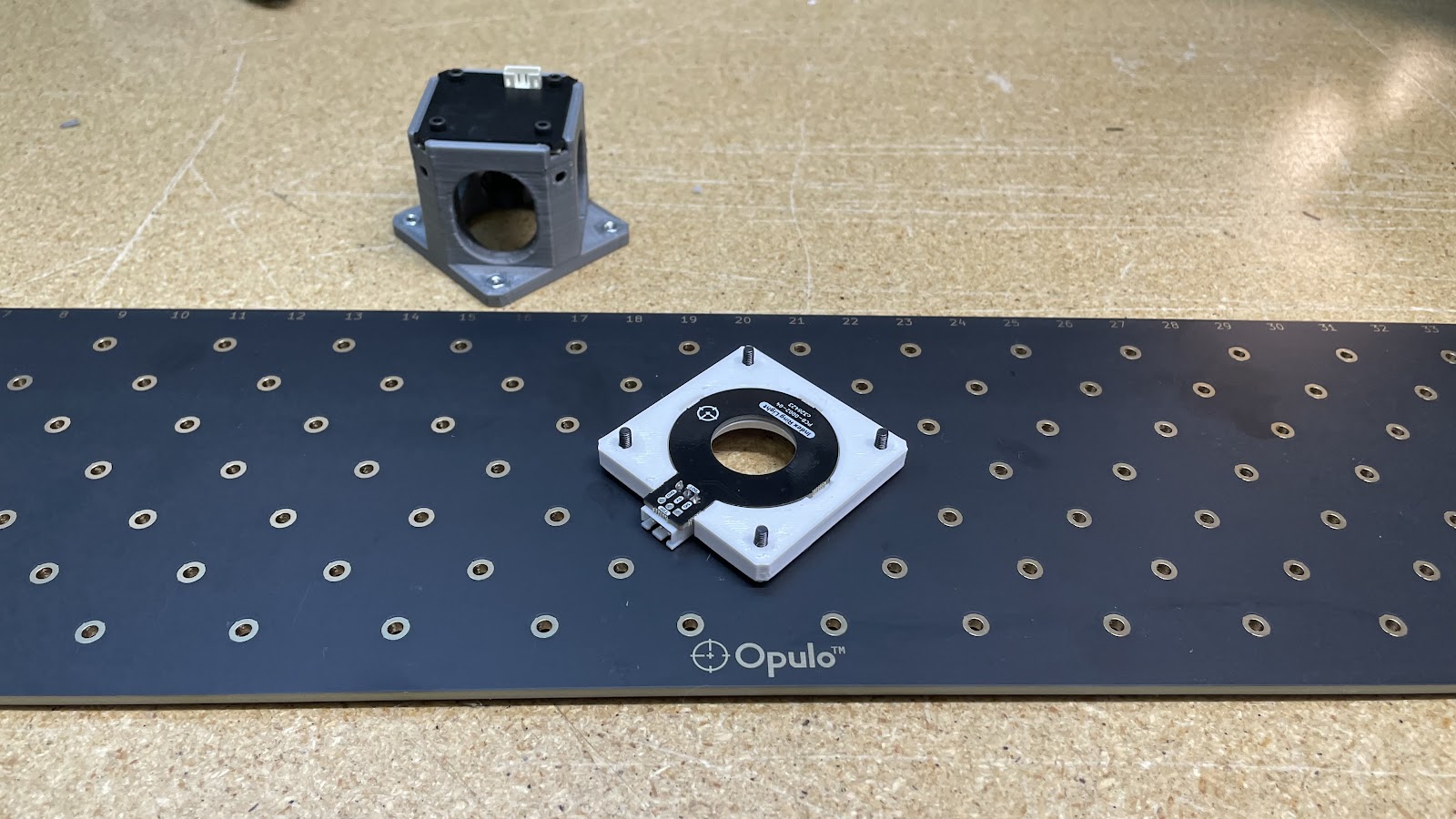

Creating bottom-camera-assembly

-

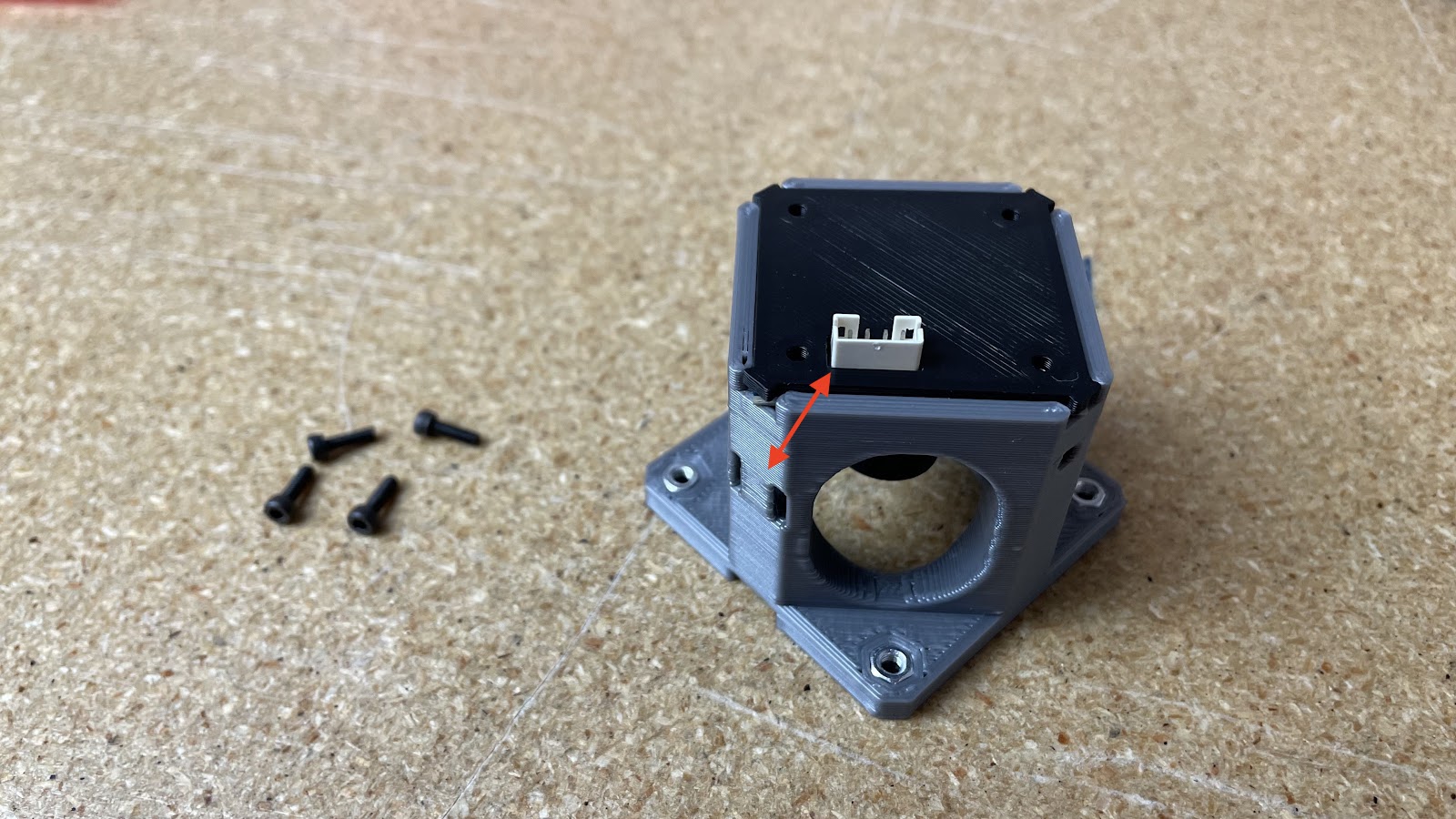

Attach

bottom-cameraandbottom-camera-covertobottom-camera-mountwith 4xM2.5x8-bolt

-

Confirm

bottom-camera's JST connector is next to the zip-tie cable strain relief feature, as indicated below:

-

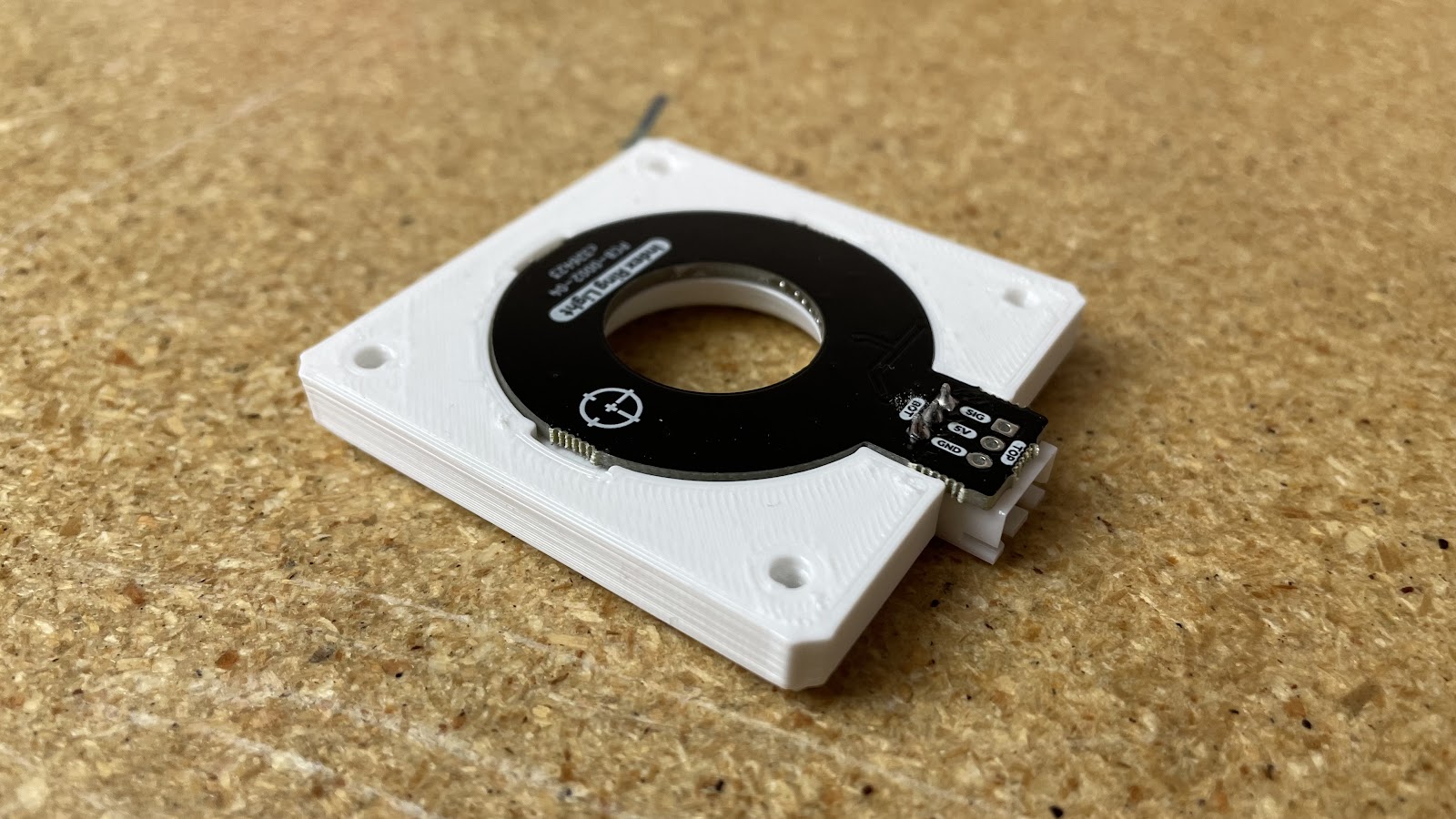

Clean

bottom-light-mountprint by removing any loose stringy plastic with a heat gun and/or razer blade (as needed) -

Install

bottom-ring-lightintobottom-light-mount

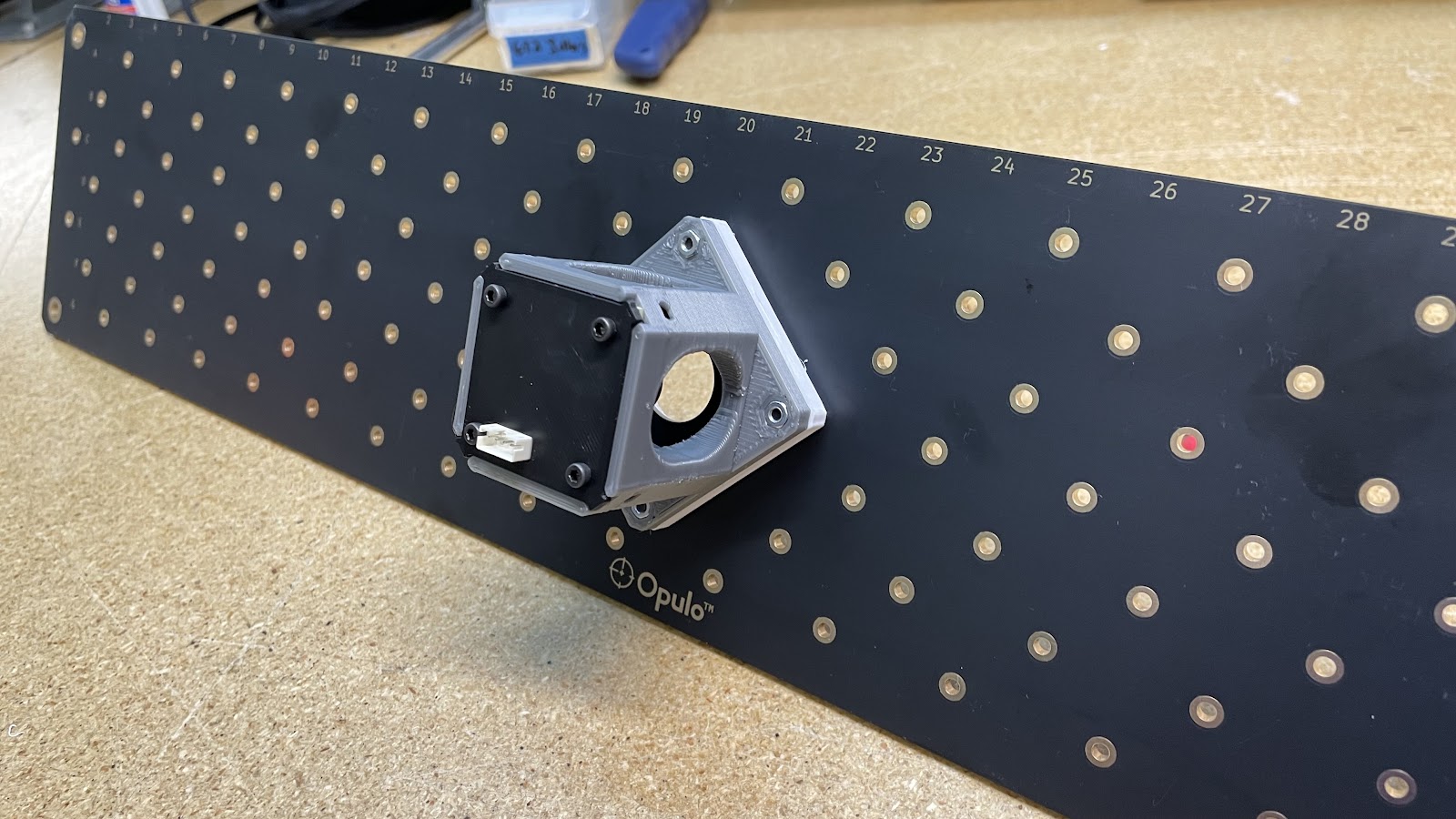

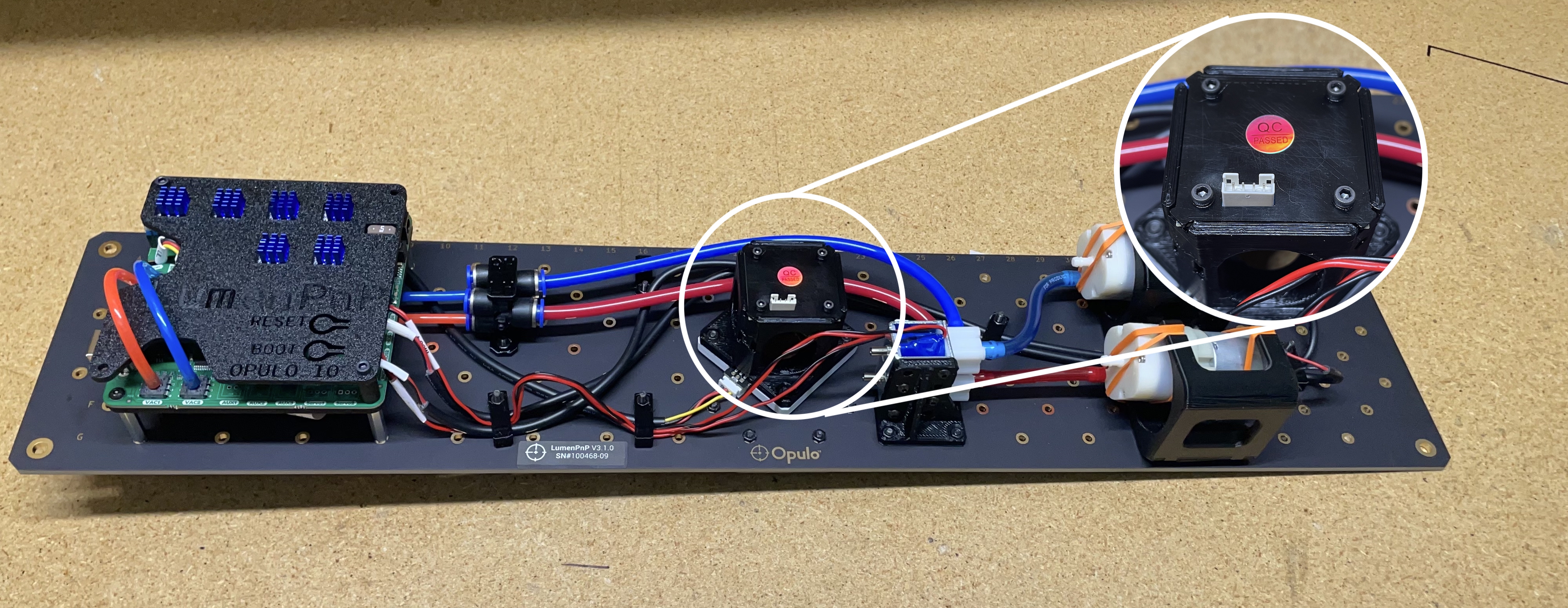

Final Assembly

Installing bottom-camera-assembly

-

Attach

bottom-camera-assemblyontostaging-platewith 4xM3x16-bolt

-

The JST cable connector found on

bottom-ring-lightshould match the orientation shown below when installed - as close to the Opulo logo as possible and in line withstaging-platecolumn 18

-

The JST cable connector found on

bottom-camerashould match the orientation shown below when installed - as close to the Opulo logo as possible

-

Plug

bottom-light-harnessintobottom-ring-light -

Plug

bottom-camera-harnessintobottom-camerabefore securing cable tobottom-camera-mountwith azip-tie

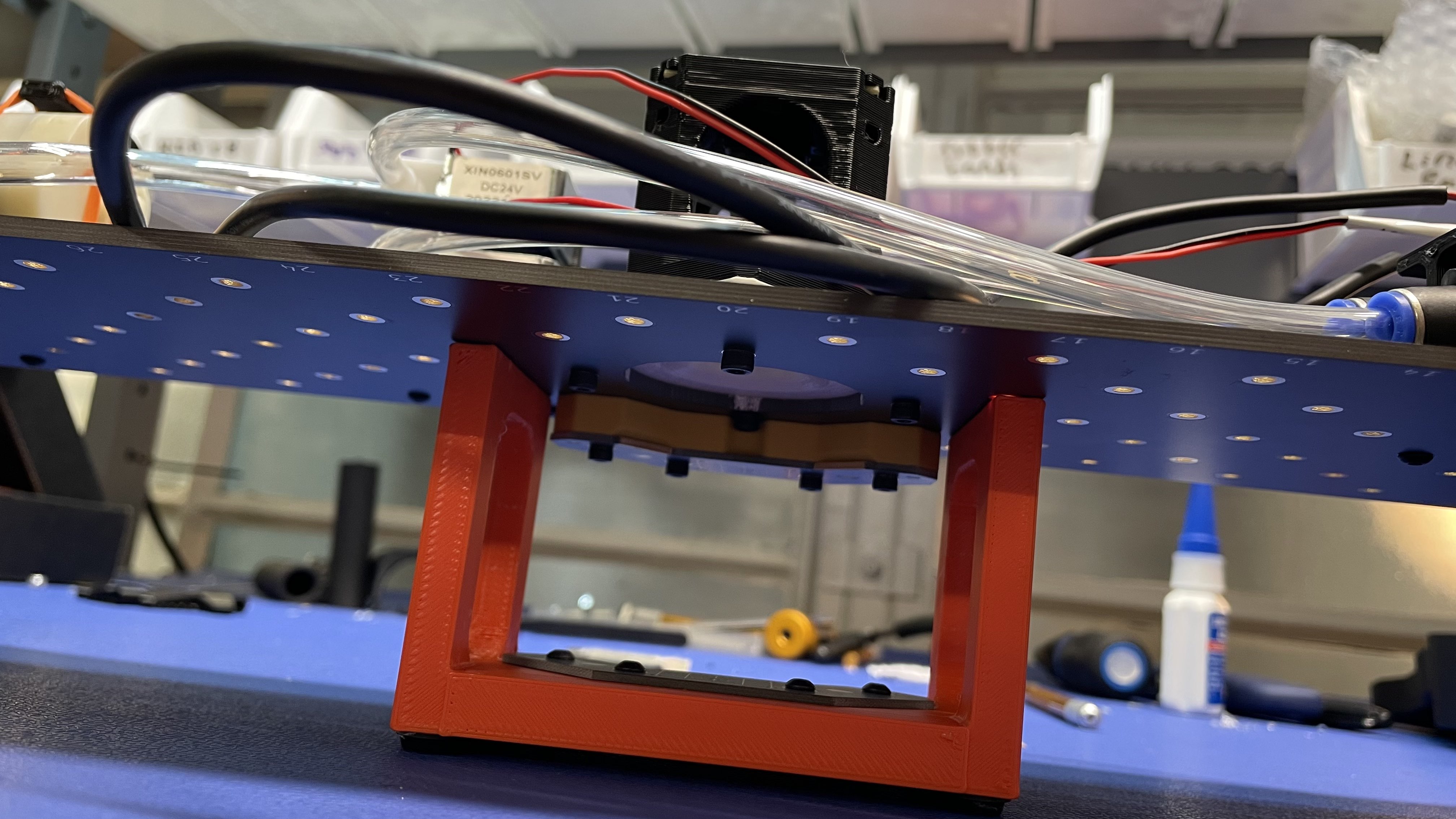

Install datum-board and datum-board-mount

- Use four

M3x16mm-boltand 4xM3-hex-nutto secure thedatum-boardanddatum-board-mounttostaging-plateon the rear of thebottom-camera, through holes: B18, A19, A21, B22. - Use a 2.5mm hex wrench and a 5.5mm (6mm if 5.5mm is unavailable) socket wrench to tighten these bolts

-

The fisheye calibration pattern should be facing down, and the gold grid lines and fiducial in the center of the Opulo logo facing upwards

Performing cable management

-

Clamp cables in the locations shown below with 3x

peek-cable-clamp, 3xm3-hex-nut, and 3xm3x14bolts -

After securing the cables, tie them up with a

rubber-band

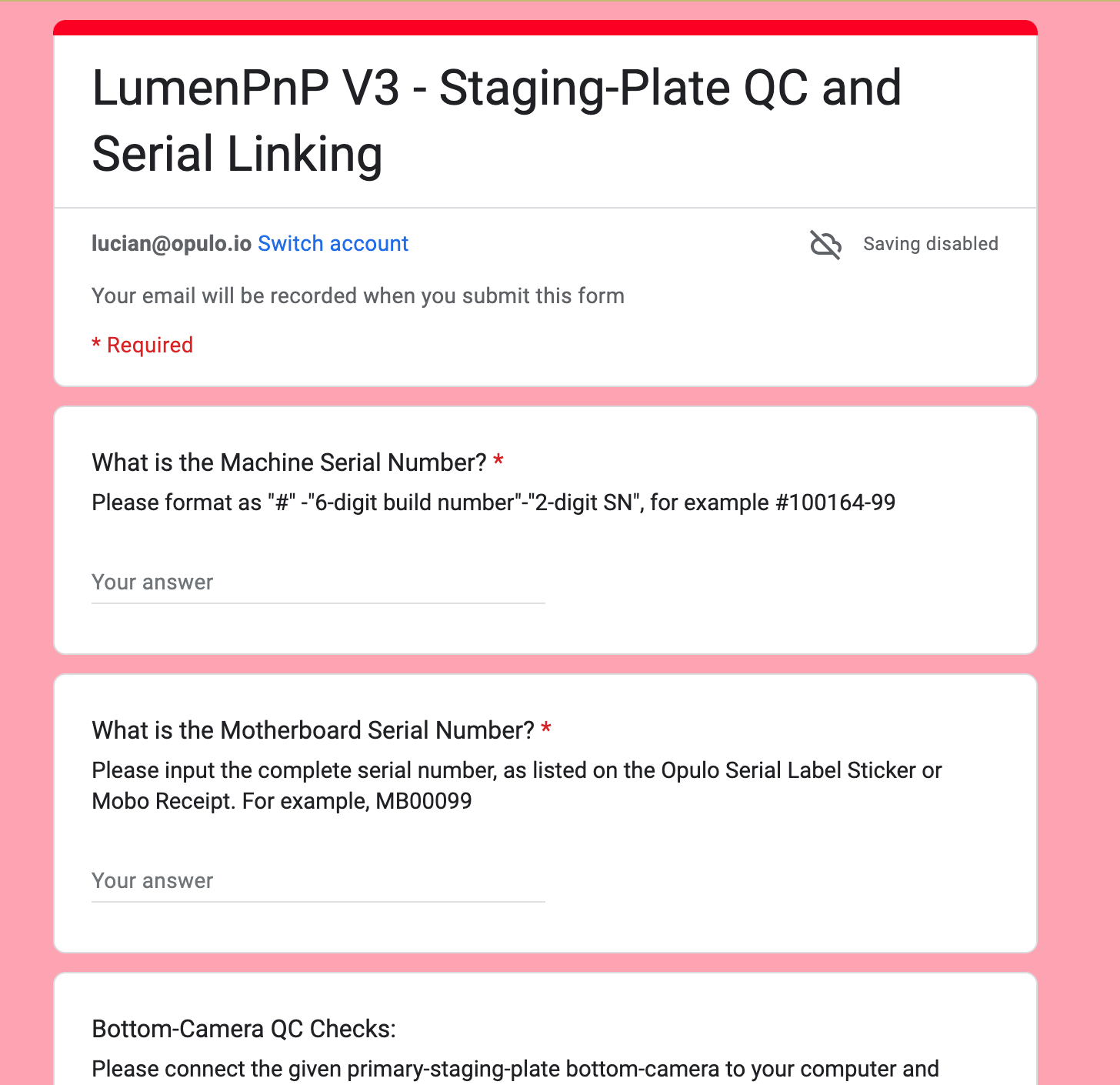

QC Checklist

- Run the

staging-plateassembly through the QC inspection form found here:

https://docs.google.com/forms/d/e/1FAIpQLSf1HXndxFzhRyJsBtHUMHoJEiU_ig9z8cUJpGCH4vcM8OR5mQ/viewform

Note

- The QC inspection form will ask you if the

bottom-camerawas correctly focused with the orange version of thebottom-camera-focus-jig

-

Use this jig in the same way the blue one is operated, while leaving the camera installed on the

staging-plate

- If the camera is out of focus, remove it from the assembly and repeat bottom-camera focusing.

Next Steps

After completing QC, perform the following steps

-

Add a

QC PASSsticker tobottom-camera-cover

-

Bring the completed

primary-staging-plateto the shelf for peer-review and pack-out